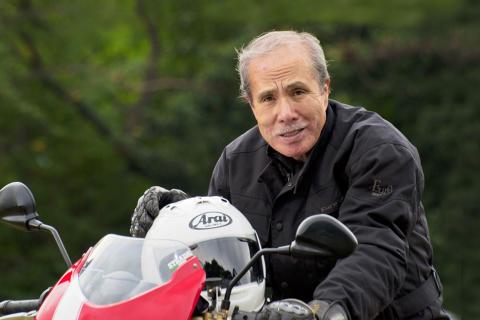

Arai’s founder, Hirotake Arai, was originally a hat maker and a hard-core motorcycle enthusiast.

Back in the 1950s when Mr. Arai was a young man riding his motorcycle, there were no helmet manufacturers in Japan. And as Japan was a closed market, it was very difficult to obtain a proper helmet. Knowing the risks of riding motorcycles firsthand, Mr. Arai knew he wanted a good helmet for his own protection.

Arai is still a small, family-owned company driven by the same mission through three generations—three generations of riders. We at Arai are motorcycle enthusiasts. We ride. We build each Arai helmet as if we’re creating it for one of our own—a brother, a father, a husband, a mother, a sister.

The Value of Arai #01: Fundamental technology for increasing shell strength

Fundamental technology for increasing shell strength. Our manufacturing process and machines were independently designed more than 40 years ago. Using these time-tested processes and machines, Arai bonds together various materials. By molding the shells in-house, Arai creates helmet shells that are strong down to their edges.

Arai’s Preforma machine, created to produce the first and last foundational layer of every Arai shell, has evolved as part of Arai’s constant efforts to improve protection, and continues to evolve even now. Currently, Arai is working to improve the even distribution of fibers in order to create uniform layers in the pre-forma by using state-of-the–art digital techniques.

In this process, Arai cuts Super Fiber to specified lengths, which is then drawn over the form by a vacuum. The flow of the fibers is controlled to efficiently scatter the fibers in certain sections according to the required thickness.

Arai’s longstanding belief is that, “It is better to accumulate improvements rather than do nothing.” As such, improvements to the pre-forma come from Arai’s desire to protect the heads of its wearers.

-

Head protection was the reason Arai began making helmets. Arai believes that improvements to a helmet’s ability to protect the wearer is not only about constructing the helmet to current impact management tests. No helmet can protect the wearer against all foreseeable impacts. Therefore, Arai’s goal is to instead continually make improvements to its helmets and seek gains in rider protection. To that end, the Arai difference is the efforts and improvements that are unseen.

Helmet shells can be manufactured in many ways. In Arai’s case, various materials are carefully combined with proprietary resins while also carefully controlling heat and pressure to minimize resin content and maximize fiber content for low weight and high strength. The key material in an Arai helmet is a glass fiber, known as Super Fiber, that is 30% stronger than standard fiberglass, but also six times more expensive.

The key to our standard shell, with high strength, is a uniform amount of fiberglass, all the way down to the very edges.

The Value of Arai #02: A Comfortable and Secure Fit Born from the Racetrack

Increasing the rider’s concentration and reducing distraction is where Arai aims to help riders’ improve their times on the track.

Despite Arai’s best efforts, no helmet can protect against all possible impacts. Acknowledging this harsh reality is tough. But this reality motivates Arai to always pursue advancements, even if small, to improve rider protection.

And so, from this pursuit, when we find something that can contribute to increased rider protection, we integrate it with the accumulation of our many past improvements further strengthening the protection ability of our helmets. That is Arai.

-

Beginning in the 1970s, Arai established a goal of making helmets that would be second to none when it came to protecting the rider’s head. Through continuous improvements to the head protection of each helmet, Arai finally could create a product that would let riders continue to have a high level of confidence in it. Putting these new helmets into practice, Arai started to enter the competitive world of racing, and received the recognition of riders around the world. Top racers in Japan and from overseas began recommending Arai helmets after using them.

Riders in America also began using the “Arai Helmet” brand for the first time. While initially skeptical of a foreign and unknown brand, the large number of racers who spoke of how comfortable the helmets were convinced American riders to use them for their recreational riding.

The initial interior shape of the EPS liners used in Arai helmets fit a wide variety of riders. Arai realized the true value of a “universal” shape for the EPS liner as it developed its helmets. That original shape for the helmet interior is still used to this day.

Arai never rested on improving the liner by research and experience. Arai continues to make improvements to fit.

Arai also entered the world of 4-wheel auto racing activities as well. In formula racing, there are high lateral Gs exerted on the driver in turns, and the helmet can feel three or even four times heavier than it actually is to the driver. In endurance racing, where the hours are long and a communication device is mounted inside the helmet, the fatiguing effect can be even higher.

So, Arai recognized that an uncomfortable fit is not an option. A firm, secure fit that does not shift or move, even when taking it easy, was and remains a high priority of Arai. Arai’s accumulated experience from its early days, understanding the problem, and finding a comfortable solution allowed Arai to make these improvements too.

The Arai helmets that resulted from these improvements efforts led to the “Arai fit” being praised, even from the best F1 drivers. This know-how has been applied to Arai’s motorcycle helmets. In accumulating those improvements, when it comes to fit, size selection is the same for even top riders or F1 drivers choosing Arai. The factory “out of the box” fit of an Arai became standard across racing and retail.

From this, Arai has the confidence to deliver the same standard size fit in all our helmets. We suggest customers first have their head circumference measured correctly and test fit their measured size. The fit of our helmet is always improving, built on amassed improvements and experiences. A soft comfortable fit and a firm fit ideal for high-speed use are not easily balanced or created in a vacuum. The Arai fit came from a base that evolved over time with experience. The fine points of which are, of course, our trade secrets.

The Value of Arai #03: The helmet that we believe in was born from a reality that testing alone cannot know.

When taken out on the road or track, even a helmet as highly regarded as an Arai may be faced with situations where it can be overwhelmed.

No helmet can protect against all possible impacts. Acknowledging this harsh reality is tough. But this reality motivates Arai to always pursue advancements, even if small, to improve rider protection.

It is that constant pursuit of gains in protection that spurs us to make helmets the way we do. Arai itself is the accumulation of all things that may lead to strengthening our helmets.

-

Arai’s founder had a personal love for motorcycles and, using his experience making industrial helmets as a basis, created the first motorcycle helmet in Japan in the early 1950s. He developed this helmet to protect his own head.

When confronted with a riding impact on a motorcycle, he realized that a liner for the helmet was necessary to reduce the transfer of impact energy to the rider’s brain. In an age where helmet standards did not exist, he conducted his own independent testing to develop what is known as an EPS liner. The EPS Liner was state of the art at the time and based on data collected from racing. Yet, the founder recognized that while lab testing helped in development, the differences in actual riding impacts warranted focused attention.

Unlike in a laboratory setting, the impact to the helmet during riding may come from any direction. Faced with these real life scenarios, Arai began building helmets with the knowledge that impacts can affect areas outside the limits of laboratory testing. Therefore, shells were built to have high strength all the way to the bottom edge of the helmet. And so, Arai’s philosophy of the accumulation of small improvements, no matter how small they may be, to further protect the head of the rider, began.

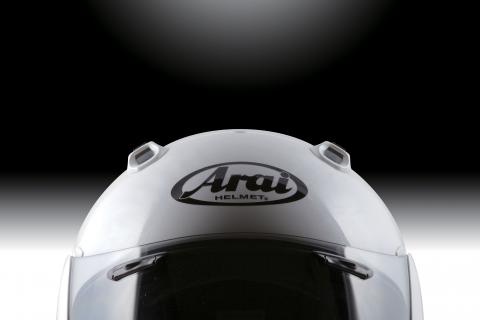

For example, the absorption ability of a helmet is inherently limited by its size and the materials it is composed of. And so, faced with the fact that a riding impact can come from any direction, it is the helmet’s ability to glance off, to avoid and minimize impact energy and potential rotational forces, that is vital. Through many years of investigation and testing, Arai believes that the shell must be round and smooth.

Arai’s basic rounder and smoother form at first glance likely does not appear to have undergone any changes since its beginnings in racing. But that is not actually the case. Through the analysis of riding impacts, slight changes have been accumulated over time to improve the shells’ ability to manage rotational energy. The result is that the form has evolved closer to that of an egg, arguably the strongest shape in nature.

It is a reality that no helmet can protect against all possible impacts. In acknowledging this reality, Arai always pursues improvements to the protective features of its helmets, even if small. And the form of our helmet is one of those important protective features on which Arai has focused.

Our Mission

Our mission has always been the protection and comfort of every person who chooses an Arai helmet. Our foundational principles of protection first, exceptional quality, and rider comfort have never been forgotten in over six decades of helmet design and manufacturing.

Small Improvements Mean Big Gains

We are always working on improving all aspects of our helmet, with protection as our primary focus. Obtaining improvements demands the dedication and focus of highly skilled artisans utilizing high-grade materials. An improvement may appear as just a small change, or may be unseen from the outside, but each one can add to an already proven design. And when many improvements are accumulated, the synergy between them provides supreme performance. This is how Arai goes after gains in protection and comfort.

Handcrafted by Skilled Workers

Every Arai helmet is meticulously handmade by craftsmen and women who are active participants in our mission to present the highest level of protection and quality. From the shell to the paint to the liner, the work is performed by hand by experienced, focused specialists.

Technical Philosophy

At Arai, safety standards such as Snell and DOT are our starting point, not our end goal. Standards are important and set minimum criteria, but while some may design their helmets to meet those minimums, “good enough” has never been good enough around here. We think about the environment you ride in, full of distracted drivers, unpredictable situations, sharp angles, and things that don’t move if you hit them. In that environment, we feel good enough just isn’t.

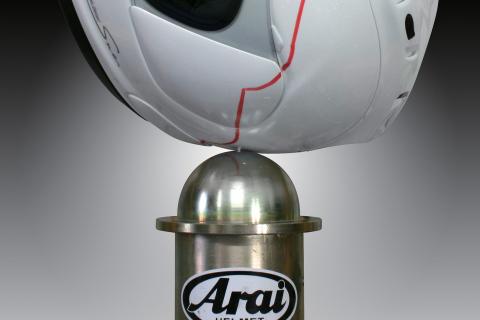

Impact Absorption is a key function of Helmet Performance

Minimizing impact energy from reaching the head is the basic function of a helmet and is what most helmet standards focus on when testing helmets. The more energy you can absorb the better it is for the rider. But all helmets are limited in their capacity to absorb or manage impact energy, due to the limitations of how big and heavy a helmet can be and still be wearable. With an outer shell only about 3mm thick and an interior EPS liner only about 4cm thick, there are limits to any helmets ability to deal with all potential impact energies.

Maximizing every aspect of helmet performance

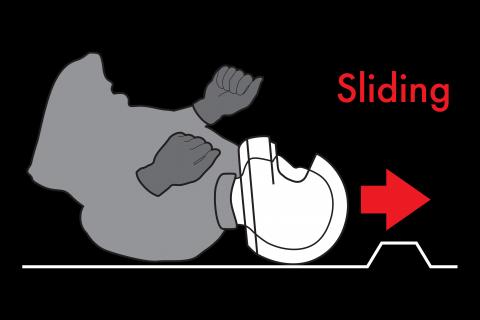

While absorbing impact energy is important, we believe that avoiding or minimizing impact energy from getting inside the helmet is where more performance can be found. A motorcycle rider traveling at street-legal highway speeds can carry more than 12 times the kinetic energy than the most stringent laboratory helmet standard tests to. This energy increases by the square of the speed, so even a small increase in speed means measurably more kinetic energy that needs to be managed by the helmet.

This kinetic energy can be avoided or minimized by sliding over or glancing off objects. Glancing off is the ability to avoid sending energy directly into the helmet and instead disperse as much of it as possible without stopping or snagging on an obstacle. Arai believes that the ability to glance off energy is one of the most important performance characteristics of a helmet.

Mitigation of Rotational Energy

The added benefit of a rounder, smoother and stronger shell that slides across uneven surfaces and glances off obstacles is that it helps to minimize oblique impacts from letting rotational forces into the helmet. This Mitigation of Rotational Energy (MoRE) prevents the need to add other measures inside the helmet, which can take away from an already limited interior liner and its ability to absorb impact energy.

By maximizing every aspect of the helmet, we can deliver more performance in a smaller and lighter helmet.

Shell Evolutions

Experience, through decades of lessons learned in the street and on the track, continues to reinforce a simple truth that a rounder, smoother and stronger shell is better able to divert impact energy by sliding across uneven surfaces and glancing off obstacles more easily, as well as helping minimize excess rotational forces.

The result is the evolution of the current Arai shell shape, similar to an egg – the strongest shape found in nature, that has a better chance of doing just that.

Egg Shaped Form

The shell’s Egg Shaped Form (ESF) is a shape that narrows at the bottom, matching the skeletal structure of the human face. The shape helps maintain the strength of the shell bottom without interfering with ingress or egress of the helmet.

Mold In-House

Mr. Hirotake Arai, motorcycle enthusiast and founder of Arai Helmet, made a helmet for his own use in the early 1950s, which was the first motorcycle helmet made in Japan. Mr. Arai began by fashioning the mold himself, and all subsequent shell molds have continued to be produced on-site. With this in-house ability, modifications and/or changes can be made from the data obtained from the initial prototype shell as needed. In addition, future updates can be done quickly and easily. A new shell mold can be made in as little as 24 hours!

Every Outer Shell Is Inspected Two Times

Shell molding by the “bag process” allows stronger helmets because it increases the fiberglass/resin content ratio. Shell materials are placed in a heated mold. Resin is added and then an expandable balloon is put into the mold. The mold is sealed and the balloon is filled with pressurized air to force the resin fully into the shell components, compressing the shell layers and forcing excess resin from the mold. The heated mold cures the resin, bonding the shell materials. As skilled as the Arai shell experts are, it is difficult to achieve a perfectly consistent shell thickness and weight using the bag process. Therefore, Arai specifies two separate and independent quality-control checks for each and every shell. The double inspection continues today after first being implemented in 1978.

Racers put our helmets to the test

From MotoGP to Formula 1, Arai is chosen by many top riders and drivers, and this offers us a wealth of feedback at the highest levels of racing. Many F1 drivers and top-level motorcycle racers use standard Arai sizes. Just think of it, standard Arai sizes are good enough for world championship contenders to perform at their peak under the most extreme race conditions. These are exactly the same size helmets customers can buy at Arai dealers – with micro fitting options included in the helmet as well!

STEPS TO BUILDING AN ARAI HELMET

Every Arai helmet is handmade, a meticulous process that combines the highest technology with nearly 70 years of old-world craftsmanship. Each helmet is a reflection of Arai’s dedication to rider protection and uncompromising quality.